People spend thousands of dollars to fix the problem of compressors. As a result, the production cost becomes high. But it is easy to fix the problems. We will discuss the air compressor troubleshooting guide. Some air compressor problems are very common. You can fix it easily. You have to know the basics of the air compressor troubleshooting guide.

You are working with your compressor. You need a good amount of pressure. Suddenly, your compressor can not deliver the pressure that you need. What are you doing in this situation? Are you waiting for the mechanics? If you do it, your time is wasted. Also, productivity decreases.

You can handle this situation own. For that, you have to read the article properly. You can know all the common air compressor troubleshooting.

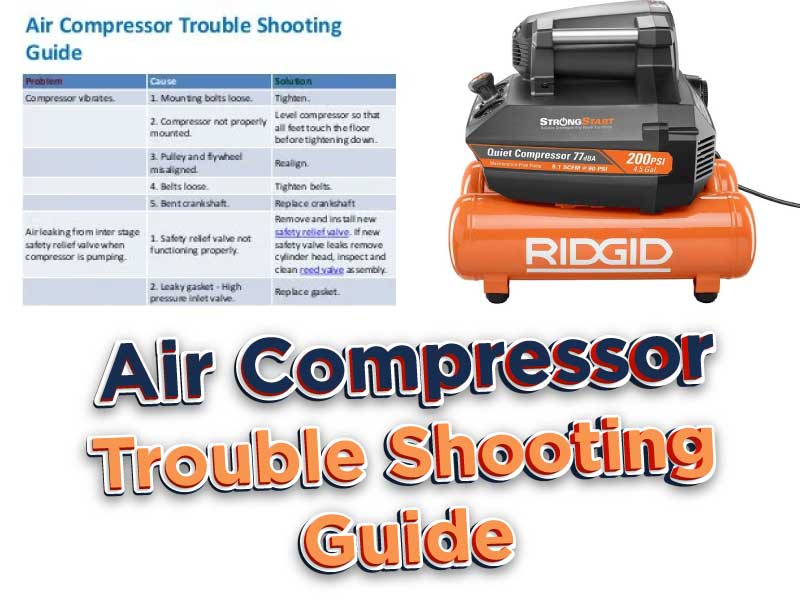

Air Compressor Troubleshooting Guide

Every compressor users face some common problems with their compressor. Like as the compressor will not start, the air compressor pump is not working, or it cannot deliver enough pressure.

These are common problems and are easy to fix. But most people don’t know how to solve it. But don’t worry. We will give you the air compressor troubleshooting guide chart. After reading the article, you can learn the air compressor troubleshooting.

- The compressor will not Start:

Does your compressor not start? You press the start button again and again. But the compressor does not operate. Check the following issues.

Cause:

- The error of electrical power.

- The power supply is not connected to the compressor

- The error in the system display

- Not fulfilling the oil level

- Wrong lead connections of the wiring system

- Overload heaters

- The error of the temperature switch

- The pressure switch is not working

Solution of the Problems:

- Check your power supply. Turn off the power switch. Then turn on it. Or, If you don’t connect the compressor with the power, connect it.

- Restart the compressor

- Push the reset button

- Check the oil level and adjust with the required level.

- Check the pressure switch and adjust it.

- The compressor starts but does not stay on

Your compressor starts but does not stay for a long time. It can happen for several reasons. Let’s see the reasons.

Causes:

- Check the oil level. If the oil level is toolless or too high it can happen.

- Check oil temperature. The compressor is not stat in high temperature.

- The error of the discharge temperature switch setting

- Overload heat of motor starter

- The high temperature of the shutdown switch

- Thermostatic mixing valve

- Lack of room ventilation and ambient air temperatures

Solution of the Problems:

A compressor stats but does not stay for a loch time. This is a standard air compressor trouble. What is the troubleshooting? You face this trouble of overheating. So you have to cool down your air tools.

- Check the oil temperature and color. Cool the oil temperature

- Filler the compressor oil

- Turn off the compressor

- Create ventilation in the room where you are working

- Check the thermostatic mixing valve

- Fix the discharge temperature switch setting

- Cool down the motor

- Create Excessive Noise

When you operate the compressor, it creates excessive noise. It is another air compressor trouble. We will point out the causes of the crisis and give you troubleshooting.

Causes:

- Lack of oil in the oil tank

- Loose bolts, belts, drive coupling, flywheel, pulley, cooler, clamps, or accessories

- Issue of the compressor floor mounting

- The problem of the main beatings

- The problem with the connecting rod bearings

- Piston hitting the valve

- Faulty crankcase

- Excessive crank end play

Solution of the Problems:

- Check the oil level and refill the oil

- Tighten all the loose parts

- Replace the vibration pads

- Tighten the bolts

- Remove the compressor cylinder head. Then check the top piston for foreign matter. Now add a new gasket and reassemble the head.

- Repair or replace the crankcase

- Adjust the crank and shim properly

- Knock trouble same as an RPM

Causes:

- Loose flywheel

- Connect with the rod bearings

- Issues with the bearings

Solution of the Problems:

- Tighten the flywheel

- Replace the rod bearings

- Replace the bearings

- Compressor use too much oil

If there has any leak, the compressor uses too much oil. That is the risk for you. There have other reasons also. Let’s see.

Causes:

- Leaks the drain valve

- The broken or loose oil return line

- Oil leak in any line

- Enter restricted air

- Piston rings with worn

- Not use the suitable oil viscosity. Read this air compressor oil guide to learn more.

- The compressor is not at the correct level. It is too tilted

- Old or bad cylinder

Solution of the Problems:

- Find out the leak and fix it

- Replace or clean the air filter

- Replace cylinder

- Replace gasket

- Tighten bolts

- Use the right viscosity

- Level the compressor

- Vibrate the Compressor

During the working time compressor doing vibrates. That is annoying and breaks concentration. If your compressor vibrates, as soon as possible solve it.

Causes:

- Loose belts

- Loose mounting bolts belts

- Bad or bent crankshaft

- The compressor is not adequate mounted

- Misaligned the flywheel and pulley

Solution of the Problems:

- Tight the belts

- Tighten the mount bolts

- Replace the crankshaft

- Before tightening, level the compressor and touch it on the floor

- Realign the flywheel and pulley

- The Compressor does not Deliver Enough Pressure

You need a good amount of pressure to complete the task. But the compressor can not deliver enough pressure. If you face like this, first check the hose. The compressor can not deliver enough pressure if there is a leak in the hose.

Causes:

- Restricted or broken the inlet valve

- Air leaks downstream

- Wrong adjustment controls

- Leak in the air filter

- Loose belts

- The hose of the compressor is too small

Solution of the Problems:

- Check the leaks and fix it

- Replace the hose

- Clean or replace the air filter

- Tighten the belts

- Air compressor trouble with the belt

Causes:

- The belts of the compressor are too loose or too tight

- Groove on the flywheel or pulley

- Pulley is out of alignment

- Pulley or flywheel wobble

Solution of the Problems:

- Adjust the belts. Tighten it properly. Not too much loose or too much tighten

- Keep smooth the flywheel

- Realign the pulley

- Check the crankshaft and replace it

- The compressor suddenly stop during the work

The compressor suddenly stops during the work. Why has the compressor stopped working? Are you tense about it? It can happen for some reasons. Let’s see the causes and troubleshooting guide.

Causes:

- Stop power supply

- Bad unloader valve

Solution of the Problems:

- Check the power supply and fix it

- Replace the unloader valve

- Entrance of air into the oil

Causes:

- Restricted air intake

- Not use the right viscosity

- Worn piston rings

- Refill more oil

- Installed piston rings upside down

Solution of the Problems:

- Replace or clean the air filter

- Use the right viscosity

- Replace the piston rings

- Refill oil as compressor require

- Replace crankshaft

- Excessive Air Temperature

Causes:

- Valves with worn

- Dirty cooling surfaces

- Enter restricted air

- The ventilation system is not good

- Bad head gasket

Solution of the Problems:

- Replace valves

- Clean the colling surfaces, discharge tubes, and intercooler

- Replace or clean the air filter

- Improve the ventilation system

- Replace the head gasket

- Compressor Delivery Pressure Slowly

For a long time using the compressor, you are not getting the pressure that you want. It is also one of the common problems of the compressor. Check all parts of the compressor and find out the problem. Then solve it. We will point out the issues.

Causes:

- The air filter is dirty

- Belts are loose

- Leak air

- Speed is too slow

- Bad cylinder head gasket

- Bad valves. The theory is worn or discharged or broken

Solution of the Problems:

- Clean the air filter

- Tighten the belts

- Tighten all the joints

- Check the speed

- Replace gasket

- Replace valves

- The compressor does not operate

Sometimes, the compressor is not an operator. There have several reasons. First, check the power supply. Then go to another side.

Causes:

- Issue of the electric supply. Not turn on the power switch

- The problem with the valve

- Defective unloader

- The pressure switch not working

Solution of the Problems:

- Turn on the power switch

- Check breaker fuse and motor

- Replace the valve

- Repair or replace the pressure switch

Read: 9 reasons why your Air Compressor keeps tripping the breaker?

- When the compressor is unloaded, the receiver does not hold pressure

Are you faced with this problem? The receiver can not hold pressure after the compressor is unloaded. This trouble creates a faulty valve. To get good performance, you must use a good quality valve.

Causes:

- Bad or fault valve

Solution of the Problems:

- Check the valve

- Clean and replace the fault valve

- Assemble the valve

- The compressor stops and does not start

Causes:

- Overload

- High temperature or over temperature

- Motor become overheating

- Motor windings are burned out

Solution of the Problems:

- Cool down the motor

- Use a heavy-duty extension cord

- Turn off the power supply and stop working for some time

Every compressor users face some common problems with their compressor. That is easy to fix. But most people don’t know how to solve it. That’s why we discussed most of the common problems of air compressors. Also, we give troubleshooting guides. Now you can fix the problem yourself.

Why You Need to Know The Air Compressor Troubleshooting Guide

Less Production Downtime

Your compressor dose does not work during working hours. If you depend on the service technicians, your valuable time is lost. So you have been able to solve compressor problems yourself. It helps you from downtime production.

Save money from service

If you know the troubleshooting guide, you can easily fix all the problems with the compressor. So the service cost of the compressor will be saved.

Prevent problems

If you know all about a compressor, you become careful. So you can prevent problems.

Less dependency on service companies

A troubleshooting guide helps you to know all the problems of compressors. So you can easily solve the problem of the compressor anytime. You no need to depend on other service companies.

Final Thought

You finished the air compressor troubleshooting guide chart. So now you have basic knowledge about compressor troubleshooting. You can fix all the problems with your compressor.

It is normal, a compressor user faces so many problems with the compressor. But you go to the expert for every problem. It is not good. You have to know the basics of compressor troubleshooting.

It helps you to save time and increase productivity. You can fix any problem with the compressor anytime and continue operation.

What are the 3 common issues and problems with a pneumatic air compressor?

You face so many issues and problems with a compressor. But some problems are very common. The 3 common issues and problems with a pneumatic air compressor are-

1. Ail leakage

2. Excessive noise and vibrating

3. Oil problem

What is the most common cause of air compressor failure?

There are so many causes of air compressor failure. The most common cause of air compressors are:

1. Exceeded the pressure level

2. The compressor will not start

3. Oil leak

How do you troubleshoot a compressor?

There are 6 steps of compressor troubleshooting.

1. Check the discharge pressure

2. Check the discharge line temperature

3. Record the compressor temperature

4. Perform a compressor valve test

5. Check the compressor motor

6. Find out the problem and solve it

What causes a compressor not to build up pressure?

This causes a compressor mot to build up the pressure:

1. Restricted or broken the inlet valve

2. Air leaks downstream

3. Wrong adjustment controls

4. Leak in the air filter

5. Loose belts

6. The hose of the compressor is too small